Polyfab

SereneTech

The SereneTech system is engineered to deliver superior noise attenuation in both residential and commercial applications, ensuring occupant comfort and compliance with acoustic standards.

Key Features:

- Multi-Layer Construction: Features a three-layer design with mineral-reinforced polypropylene to effectively dampen sound vibrations.

- Noise Reduction: Achieves sound attenuation levels up to 16 dB, reducing noise transfer and enhancing environmental comfort.

- Thermal Resistance: Capable of withstanding continuous wastewater temperatures up to 95°C, suitable for various plumbing needs.

- Corrosion Resistance: Offers excellent resistance to corrosion, ensuring long-term durability and reliability.

- Environmental Compliance: Made from recyclable, non-toxic polypropylene, supporting sustainable building practices.

- Applications: Ideal for use in residential buildings, offices, and educational institutions where moderate noise reduction is sufficient to improve indoor acoustics.

Polyfab

SereneTech+

Designed for environments requiring enhanced noise control, such as hospitals, hotels, and high-rise buildings, SereneTech+ system meets stringent acoustic and safety standards.

- Key Features:

- Enhanced Multi-Layer Design: Incorporates a three-layer structure with a mineral-reinforced polypropylene core for advanced sound dampening capabilities.

- Superior Noise Reduction: Provides noise attenuation up to 20 dB, effectively meeting high-level acoustic requirements.

- High-Temperature Tolerance: Handles continuous wastewater temperatures up to 95°C, suitable for demanding applications.

- Fire Resistance: Compiles with fire safety standards, classified as B2 according to DIN 4102, ensuring safety in building design.

- Chemical Resistance: Resistant to aggressive chemicals, ensuring longevity even in challenging environments.

SereneTech

Technical Specifications

| Properties | Value | Standard |

|---|---|---|

| Brand | SereneTech, SereneTech+ | |

| Pipe Material | PP/PP mineral filled/ PP (PP/PP+MD /PP) Homo/ Co-polymer PP for external (Blue) and the internal (White) layer. Compound of PP and PP-MD for the middle (off White layer) |

|

| Fittings Material | PP mineral filled (PP-M) | |

| Rubber Material | BISMATH 1000, EPDM | |

| Colour | Pipes Inner Layer: White RAL 9003 Middle Layer: Off White RAL 9010 Outer Layer: Night Blue RAL 5022 Fittings: Night blue RAL 5022 |

|

| Diameter | 32-160mm | |

| Wall thickness | Up to 5.3mm, Depending on the diamter sizes | |

| Pipe Series | S-16, SN4 (Ring Stiffness > 4kN/m2) | |

| Structure | Pipe: Extruded 1 Layer and 3 Layer. Fittings:Moulded Single Wall |

|

| Application | High and low temperature waste and drainage systems inside the building or anchored externally to the walls of the building (application area B) or laid directly in concrete; ventilation of waste systems: gravity rainwater drainage systems. |

|

| Connection | Push-fit sockets equipped with elastomer rubber seals | |

| Temperature Sustainability | Water Temp. up to 95°c/203°F (intermittent) or 90°c/194°F(continuos) | |

| Fire Behavior | B2 (normally inflammable) DIN 4102-1 E(normally inflammable) EN 13501-1 |

|

| Standards and Approvals | Manufactured as per EN 1451, DIN 19560, EN 14366, ISO 12354, DIN 4109 | |

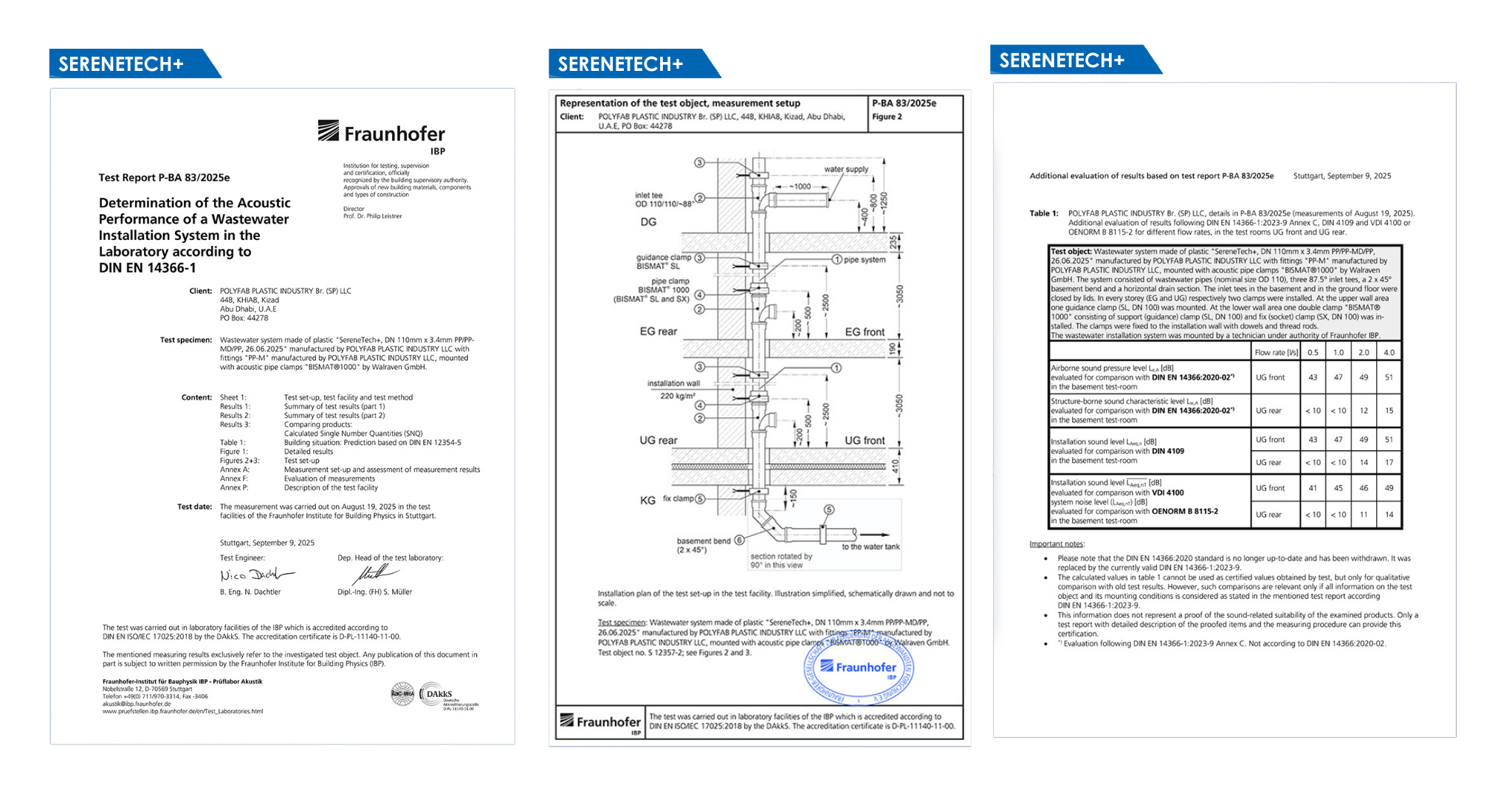

| Sound Insulation | 0,5 1/s 13bD, 1,0 1/s 1 dB, 2,0 1/s 15 dB, 4, 0 1/s 19 dB All tests were carried out by Franunhofer in Germany |

|

| Acoustic Performance Report | Test Report P-BA 82/2025e Test Report P-BA 83/2025e |

|

| Chemical Reistance | Waste Water with pH value 2-12 | |

| UV Resistance | Resistance to UV | |

| Maximum Pressure | Up to 2 bar | |

| Density | <1.9 g/cm3 | EN ISO 1183 |

| MFR(230/2.16) | <5.0 g/10min | EN ISO 1133 |

| Elangation @break | >600% | ISO 6259 |

| Tensile Strength | >18 MPa | ISO 6259 |

| Elasticity Modulus | >100 MPa | ISO 527 |

| Coeffient of Liner Expansion | 0.9 mm/mK | |

| Impact Resistance | TIR<10% | ISO 3127 |

| Longitudinal Reversion | <2% | ISO 2505 |

| Hologen & Cadmium Availability | Free of Halogen or Cadmium | |

| Design Life Expectancy | 50 years |

Polyfab

SereneTech Acoustic Pipe Introduction

1. Inner Layer

- Material: PPB

- Colour: White RAL 9003

- High chemical resistance

- Resistance to high temperature

- Very smooth flow

2. Middle Layer

- Material: PP-MD (mineral filed Polypropylene)

- Colour: Off White RAL 9010

- High density material

- Reduces sound waves and defuses emission

3. Outer Layer

- Material: PPB

- Colour: Night Blue RAL 5022

- Resistance to external impact/tension

- Very smooth surface

- Resistance to weathering effects

4. Push Fit Socket with Lip Seal

- Colour: Black

- Pre-lubricated EPDM elastomer

- Watertight seal

- Movement for expansion

- Material: PP-MD (mineral filled Polypropylene)

- Colour: Night Blue RAL 5022

- High density material

- Reduces sound waves and defuses emission

- High mechanical resistance

SereneTech by Polyfab is an advanced, low-noise soil and waste drainage system crafted from mineral-reinforced polypropylene (PP-MD). This innovative system features a high-mass, three-layer co-extruded pipe design, meticulously engineered to deliver superior acoustic attenuation in gravity drainage applications. The inner layer provides excellent chemical resistance and optimal flow performance, while the intermediate mineral-reinforced core enhances sound dampening through increased mass. The outer layer offers robust structural strength and impact resistance, ensuring durability under demanding conditions. Equipped with push-fit sockets joints, factory-applied lubricant, and integrated EPDM elastomeric seats, SereneTech guarantees reliable, watertight connections and effortless installation—eliminating the need for additional sealants or specialized tools.

Inner and Outer Layers: Made of PP-B, providing strength and durability.

Middle Layer: Composed of mineral-filled PP-MD, designed to maximize sound absorption. This innovative composition effectively minimizes noise from wastewater flow, creating a quieter environment, making it ideal for hospitals, hotels, nursing homes, office complexes, and residential high-rises. The materials are corrosion-resistant and capable of withstanding harsh wastewater chemicals, ensuring long service life and reliable performance.

Pipes and fittings are assembled using push-fit sockets with EPDM elastomeric sealing rings, guaranteeing leak-proof and secure joints. The system is suitable for both high and low-temperature fluid discharge, whether within a building or buried underground, and complies with BS EN 12056 standards.

SereneTech

Manufacturing Standards Compliance

Polyfab adheres to a comprehensive set of international and national standards to ensure the highest quality and safety in our products and solutions. Our compliance includes:

| Standard | Scope |

|---|---|

| EN 14366 | Laboratory measurement of noise from watewater installations |

| EN/ISO 12354 | Building acoustics - Estimation of acoustic performance of buildings from the performace of elements |

| EN 13501 | Fire classification of construction projects and building elements |

| DIN 4102 | Fire behaviour of building materials and building components |

| DIN 19560 | Polypropylene (PP) pipe and fittings for hot water-resistant waste and soil discharge systems inside buildings |

| EN 1451 | Plastic piping systems for soil and waste discharge (low and high temperature) within the building structure, including specification for pipes, fittings, and systems |

| EN 1411 & EN 744 | Plastic piping and ducting systems - Resistance to external blows (Round-the-Clock Method) |

| EN 1055 | Plastic piping systems, Thermoplastic piping systems for soil and waste discharge inside buildings. Test method for resistance to elevated temperature cycling. |

| EN 1054 | Plastic piping system. Thermoplastic piping systems for soil and waste discharge. Test Method for airtightness of joints |

| EN 763 | Plastic Piping adn Ducting Systems - Injection-Moulded Themoplastics Fittings-Test Method for Visually Assessing Effects of Heating |

| EN 743 | Plastics piping and ducting systems- Thermoplastic pipes - Determination of the longitudinal reversion |

| DN 4109 | Requirements for Sound insulation in buildings |

polyfab

SereneTech Acoustic Drainage System

The SereneTech system is engineered to deliver superior noise attenuation in both residential and commercial applications, ensuring occupant comfort and compliance with acoustic standards.

Key Features:

- Multi-Layer Construction: Features a three-layer design with mineral-reinforced polypropylene to effectively dampen sound vibrations.

- Noise Reduction: Achieves sound attenuation levels up to 16 dB, reducing noise transfer and enhancing environmental comfort.

- Thermal Resistance: Capable of withstanding continuous wastewater temperatures up to 95°C, suitable for various plumbing needs.

- Corrosion Resistance: Offers excellent resistance to corrosion, ensuring long-term durability and reliability.

- Environmental Compliance: Made from recyclable, non-toxic polypropylene, supporting sustainable building practices.

- Applications: Ideal for use in residential buildings, offices, and educational institutions where moderate noise reduction is sufficient to improve indoor acoustics.

| Nominal Size | Mean Outside Diameter (mm) | Wall Thickness S16 (SDR-33) |

Length | ||

|---|---|---|---|---|---|

| DN | Min. | Max. | e-Min. | e-Max. | L(mm) |

| 32 | 32.0 | 32.3 | 1.8 | 2.2 | 1000 |

| 32 | 32.0 | 32.3 | 1.8 | 2.2 | 2000 |

| 32 | 32.0 | 32.3 | 1.8 | 2.2 | 3000 |

| 32 | 32.0 | 32.3 | 1.8 | 2.2 | 4000 |

| 40 | 40.0 | 40.3 | 1.8 | 2.2 | 1000 |

| 40 | 40.0 | 40.3 | 1.8 | 2.2 | 2000 |

| 40 | 40.0 | 40.3 | 1.8 | 2.2 | 3000 |

| 40 | 40.0 | 40.3 | 1.8 | 2.2 | 4000 |

| 50 | 50.0 | 50.3 | 1.8 | 2.2 | 1000 |

| 50 | 50.0 | 50.3 | 1.8 | 2.2 | 2000 |

| 50 | 50.0 | 50.3 | 1.8 | 2.2 | 3000 |

| 50 | 50.0 | 50.3 | 1.8 | 2.2 | 4000 |

| 75 | 75.0 | 75.4 | 2.3 | 2.8 | 1000 |

| 75 | 75.0 | 75.4 | 2.3 | 2.8 | 2000 |

| 75 | 75.0 | 75.4 | 2.3 | 2.8 | 3000 |

| 75 | 75.0 | 75.4 | 2.3 | 2.8 | 4000 |

| 90 | 90.0 | 90.4 | 2.5 | 3 | 1000 |

| 90 | 90.0 | 90.4 | 2.5 | 3 | 2000 |

| 90 | 90.0 | 90.4 | 2.5 | 3 | 3000 |

| 90 | 90.0 | 90.4 | 2.5 | 3 | 4000 |

| 110 | 110.0 | 110.4 | 3.4 | 4 | 1000 |

| 110 | 110.0 | 110.4 | 3.4 | 4 | 2000 |

| 110 | 110.0 | 110.4 | 3.4 | 4 | 3000 |

| 110 | 110.0 | 110.4 | 3.4 | 4 | 4000 |

| 160 | 160.0 | 160.5 | 4.9 | 5.6 | 1000 |

| 160 | 160.0 | 160.5 | 4.9 | 5.6 | 2000 |

| 160 | 160.0 | 160.5 | 4.9 | 5.6 | 3000 |

| 160 | 160.0 | 160.5 | 4.9 | 5.6 | 4000 |

polyfab

SereneTech+ Acoustic Drainage System(High Performance)

Designed for environments requiring enhanced noise control, such as hospitals, hotels, and high-rise buildings, SereneTech+ system meets stringent acoustic and safety standards.

- Key Features:

- Enhanced Multi-Layer Design: Incorporates a three-layer structure with a mineral-reinforced polypropylene core for advanced sound dampening capabilities.

- Superior Noise Reduction: Provides noise attenuation up to 20 dB, effectively meeting high-level acoustic requirements.

- High-Temperature Tolerance: Handles continuous wastewater temperatures up to 95°C, suitable for demanding applications.

- Fire Resistance: Compiles with fire safety standards, classified as B2 according to DIN 4102, ensuring safety in building design.

- Chemical Resistance: Resistant to aggressive chemicals, ensuring longevity even in challenging environments.

| Nominal Size | Mean Outside Diameter (mm) | Wall Thickness SereneTech+ | Length | ||

|---|---|---|---|---|---|

| DN | Min. | Max. | e-Min. | e-Max. | L(mm) |

| 50 | 50.0 | 50.3 | 3 | 3.6 | 1000 |

| 50 | 50.0 | 50.3 | 3 | 3.6 | 2000 |

| 50 | 50.0 | 50.3 | 3 | 3.6 | 3000 |

| 50 | 50.0 | 50.3 | 3 | 3.6 | 4000 |

| 75 | 75.0 | 75.4 | 3.5 | 4 | 1000 |

| 75 | 75.0 | 75.4 | 3.5 | 4 | 2000 |

| 75 | 75.0 | 75.4 | 3.5 | 4 | 3000 |

| 75 | 75.0 | 75.4 | 3.5 | 4 | 4000 |

| 90 | 90.0 | 90.4 | 4.6 | 5.1 | 1000 |

| 90 | 90.0 | 90.4 | 4.6 | 5.1 | 2000 |

| 90 | 90.0 | 90.4 | 4.6 | 5.1 | 3000 |

| 90 | 90.0 | 90.4 | 4.6 | 5.1 | 4000 |

| 110 | 110.0 | 110.4 | 5.3 | 5.9 | 1000 |

| 110 | 110.0 | 110.4 | 5.3 | 5.9 | 2000 |

| 110 | 110.0 | 110.4 | 5.3 | 5.9 | 3000 |

| 110 | 110.0 | 110.4 | 5.3 | 5.9 | 4000 |

| 160 | 160.0 | 160.5 | 5.6 | 6.3 | 1000 |

| 160 | 160.0 | 160.5 | 5.6 | 6.3 | 2000 |

| 160 | 160.0 | 160.5 | 5.6 | 6.3 | 3000 |

| 160 | 160.0 | 160.5 | 5.6 | 6.3 | 4000 |

polyfab

SereneTech Acoustic Fittings

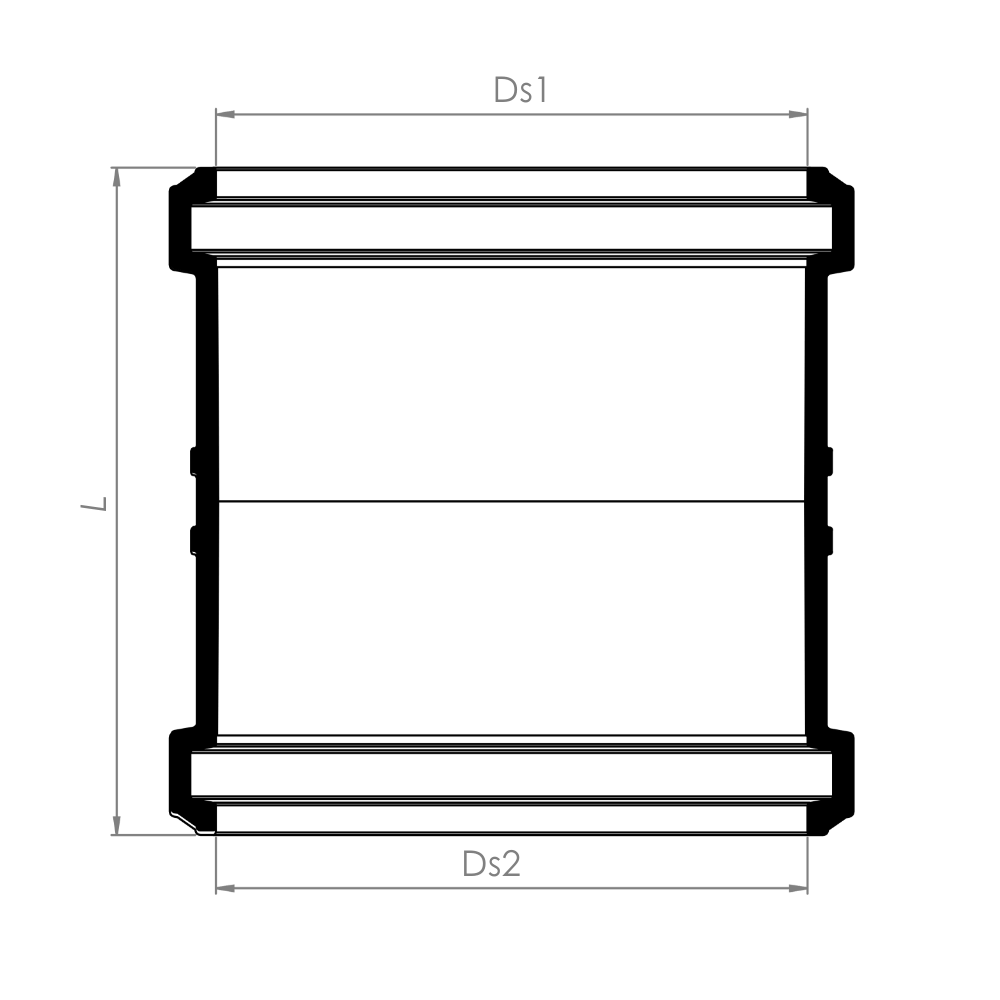

Double Socket Coupler

| Diameter - DN | L - mm | Ds1 - mm | Ds2 - mm | Z1 - mm |

|---|---|---|---|---|

| 32 | 97 | 32 | 32 | 3 |

| 40 | 98 | 40 | 40 | 3 |

| 50 | 99 | 50 | 50 | 3 |

| 75 | 108 | 75 | 75 | 3 |

| 90 | 115 | 90 | 90 | 5 |

| 110 | 125 | 110 | 110 | 5 |

| 160 | 150 | 160 | 160 | 5 |

Repair Coupler

| Diameter - DN | L - mm | Ds1 - mm | Ds2 - mm |

|---|---|---|---|

| 32 | 97 | 32 | 32 |

| 40 | 98 | 40 | 40 |

| 50 | 99 | 50 | 50 |

| 75 | 108 | 75 | 75 |

| 90 | 115 | 90 | 90 |

| 110 | 125 | 110 | 110 |

| 160 | 150 | 160 | 160 |

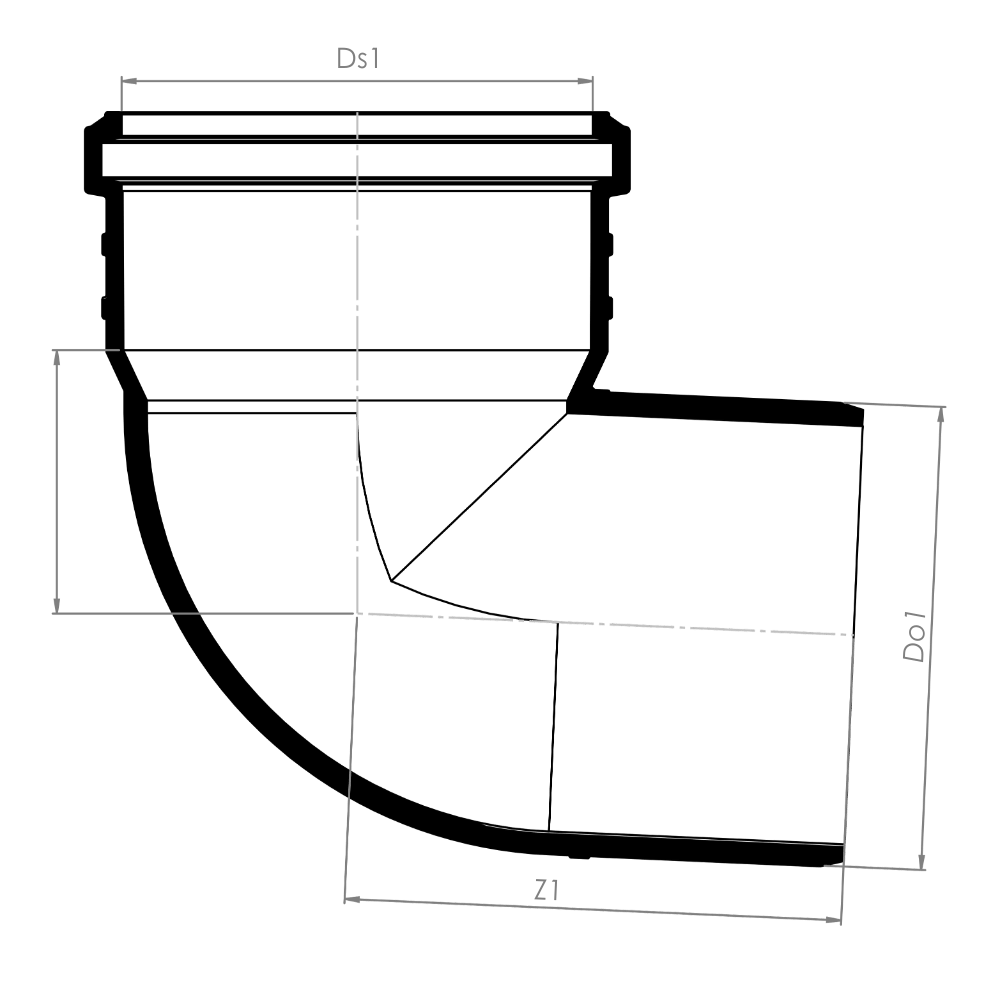

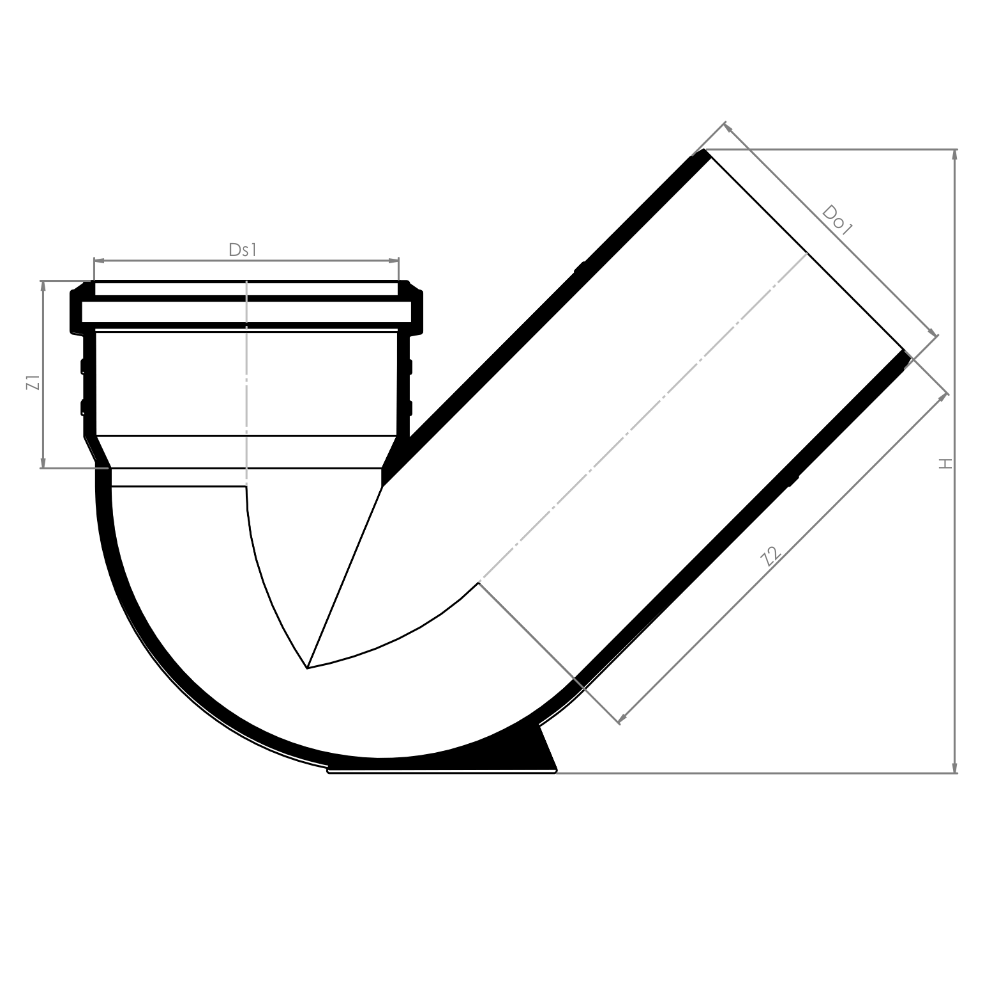

Bend 45°

| Diameter - DN | Angle | Ds1 - mm | Do1 - mm | Z1 - mm | Z2 - mm |

|---|---|---|---|---|---|

| 32 | 45 | 32 | 32 | 41 | 11 |

| 40 | 45 | 40 | 40 | 45 | 15 |

| 50 | 45 | 50 | 50 | 64 | 18 |

| 75 | 45 | 75 | 75 | 71.5 | 25 |

| 90 | 45 | 90 | 90 | 74.5 | 28 |

| 110 | 45 | 110 | 110 | 87.5 | 34 |

| 160 | 45 | 160 | 160 | 110.5 | 44 |

Bend 87.5°

| Diameter - DN | Angle | Ds1 - mm | Do1 - mm | Z1 - mm | Z2 - mm |

|---|---|---|---|---|---|

| 32 | 87.5 | 32 | 32 | 51 | 20 |

| 40 | 87.5 | 40 | 40 | 59 | 23 |

| 50 | 87.5 | 50 | 50 | 75 | 30 |

| 75 | 87.5 | 75 | 75 | 91.5 | 43 |

| 90 | 87.5 | 90 | 90 | 102.5 | 50 |

| 110 | 87.5 | 110 | 110 | 117.5 | 62 |

| 160 | 87.5 | 160 | 160 | 152.5 | 69 |

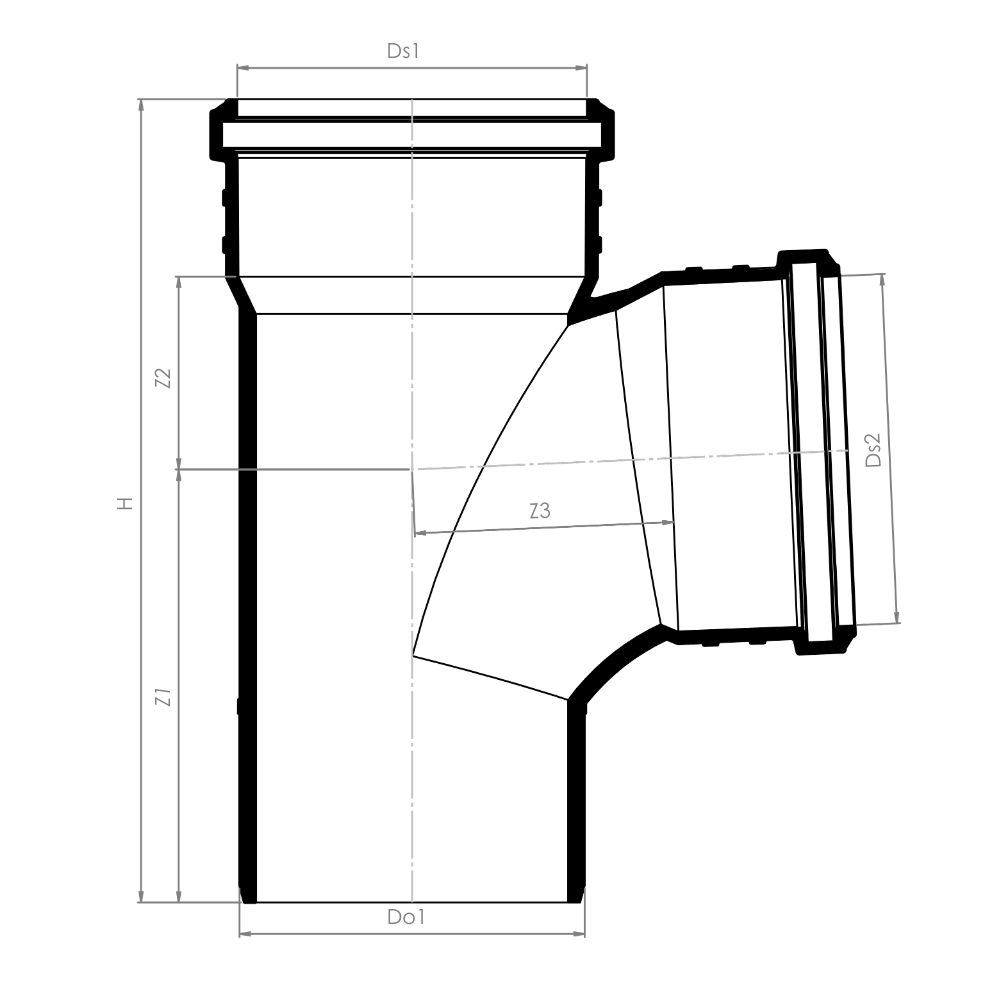

Single Branch 87.5°

| Diameter DN | Angle | Ds1 mm | Ds2 mm | Do1 mm | Z1 mm | Z2 mm | Z3 mm | H mm |

|---|---|---|---|---|---|---|---|---|

| 32 | 87.5 | 32 | 32 | 32 | 24 | 20 | 20 | 130 |

| 40 | 87.5 | 40 | 40 | 40 | 38 | 25 | 25 | 140 |

| 50 | 87.5 | 50 | 50 | 50 | 84 | 29 | 41 | 159 |

| 75 | 87.5 | 75 | 75 | 75 | 110 | 40 | 57 | 200.5 |

| 90 | 87.5 | 90 | 90 | 90 | 126 | 48 | 68 | 226 |

| 110 | 87.5 | 110 | 110 | 110 | 138 | 61.5 | 82.5 | 256 |

| 160 | 87.5 | 160 | 160 | 160 | 145 | 67 | 89 | 259 |

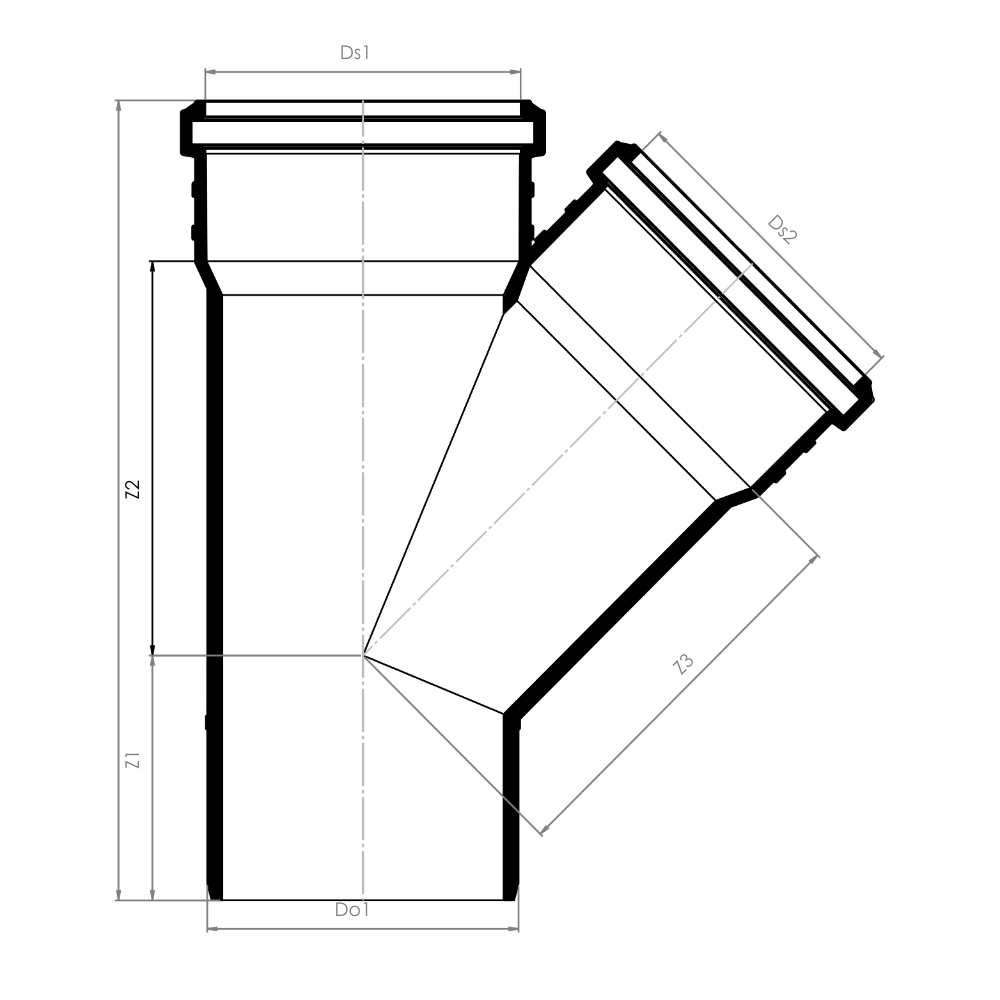

Single Branch 45°

| Diameter DN | Angle | Ds1 mm | Ds2 mm | Do1 mm | Z1 mm | Z2 mm | 3 mm | H mm |

|---|---|---|---|---|---|---|---|---|

| 32 | 45 | 32 | 32 | 32 | 54 | 48 | 48 | 150 |

| 40 | 45 | 40 | 40 | 40 | 58 | 59 | 59 | 160 |

| 50 | 45 | 50 | 50 | 50 | 61 | 65 | 65 | 172 |

| 75 | 45 | 75 | 75 | 75 | 71.5 | 95 | 95 | 216.5 |

| 90 | 45 | 90 | 90 | 90 | 77.5 | 114 | 114 | 244.5 |

| 110 | 45 | 110 | 110 | 110 | 86 | 138.5 | 138.5 | 281 |

| 160 | 45 | 160 | 160 | 160 | 109 | 201.5 | 201.5 | 376 |

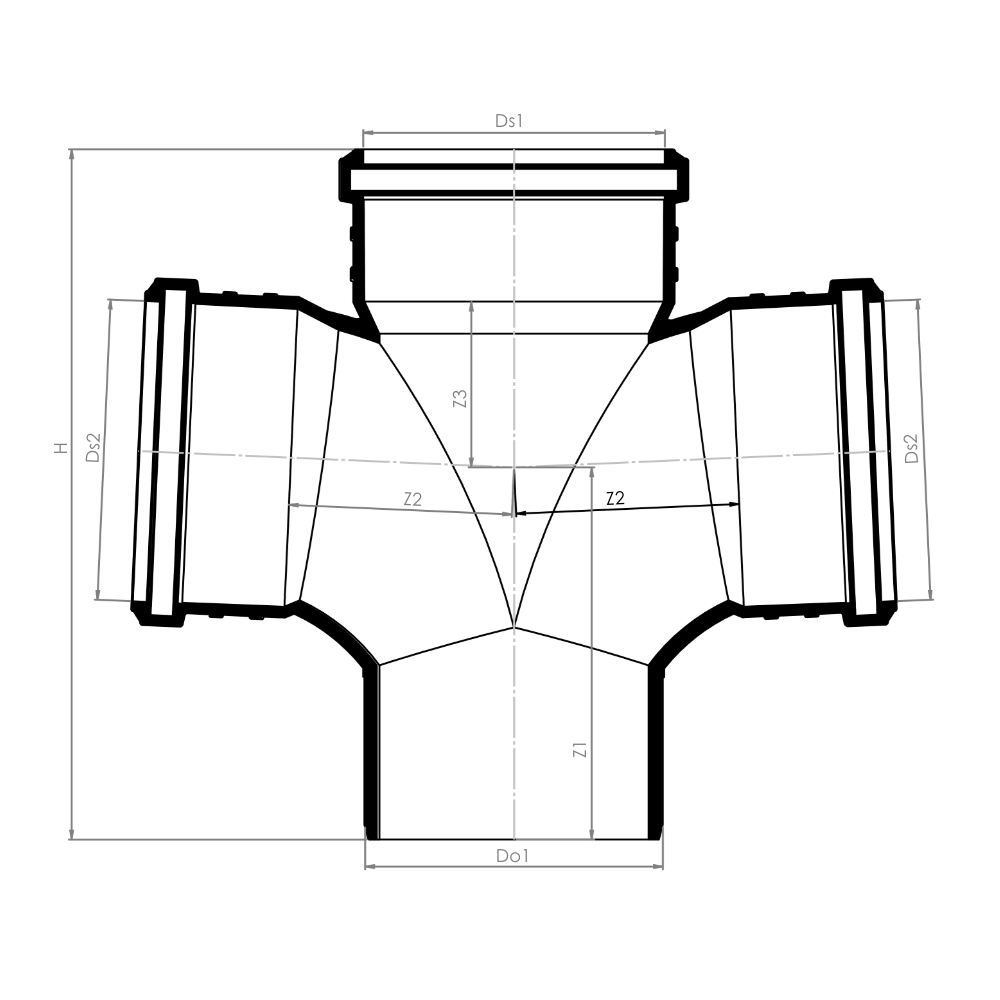

Double Branch 87.5°

| Diameter DN | Angle | Ds1 mm | Ds2 mm | Do1 mm | Z1 mm | Z2 mm | Z3 mm | H mm |

|---|---|---|---|---|---|---|---|---|

| 110 | 45 | 110 | 110 | 110 | 138 | 61.5 | 82.5 | 256 |

| 160 | 45 | 160 | 160 | 160 | 145 | 67 | 89 | 259 |

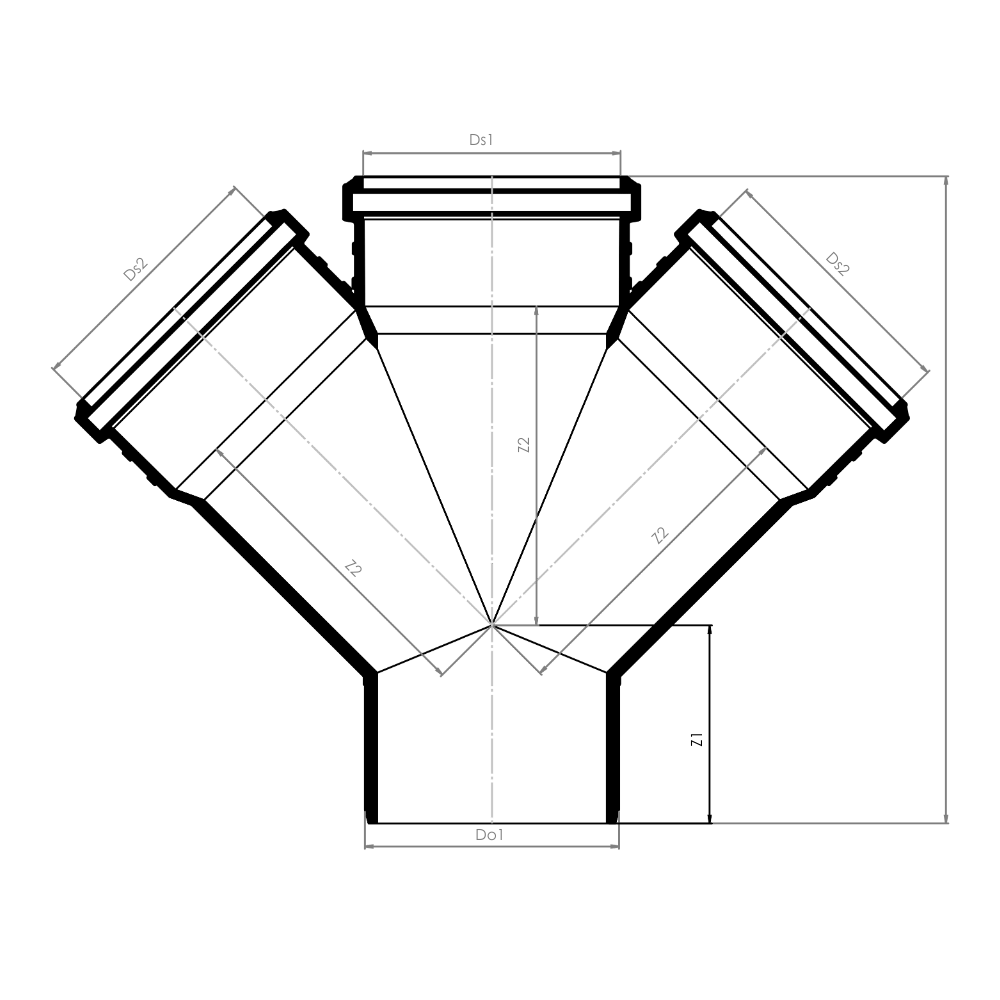

Double Branch 45°

| Diameter DN | Angle | Ds1 mm | Ds2 mm | Do1 mm | Z1 mm | Z2 mm | H mm |

|---|---|---|---|---|---|---|---|

| 110 | 45 | 110 | 110 | 110 | 86 | 138.5 | 281 |

| 160 | 45 | 160 | 160 | 160 | 109 | 201.5 | 376 |

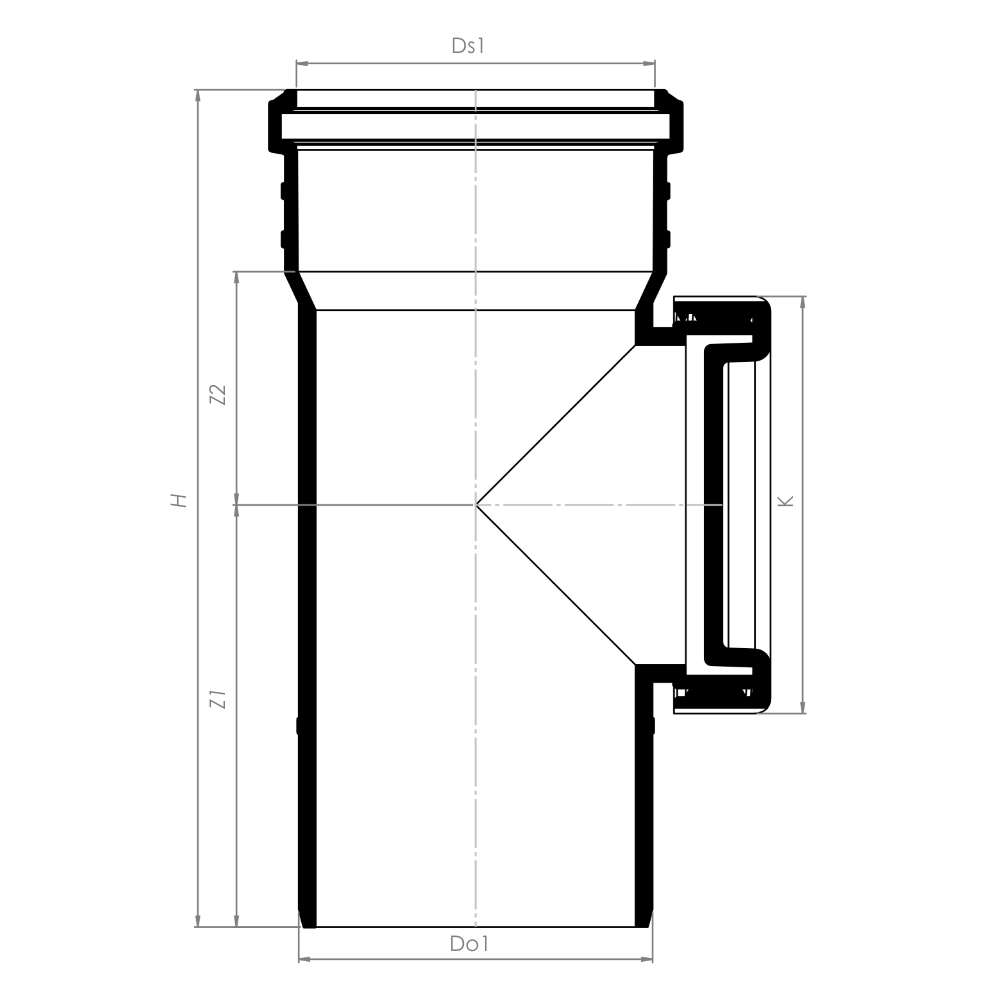

Access

| Diameter DN | Ds1 mm | Do1 mm | Z1 mm | Z2 mm | K mm | H mm |

|---|---|---|---|---|---|---|

| 110 | 110 | 110 | 129 | 72 | 130 | 174 |

| 160 | 160 | 160 | 135 | 68 | 130 | 213 |

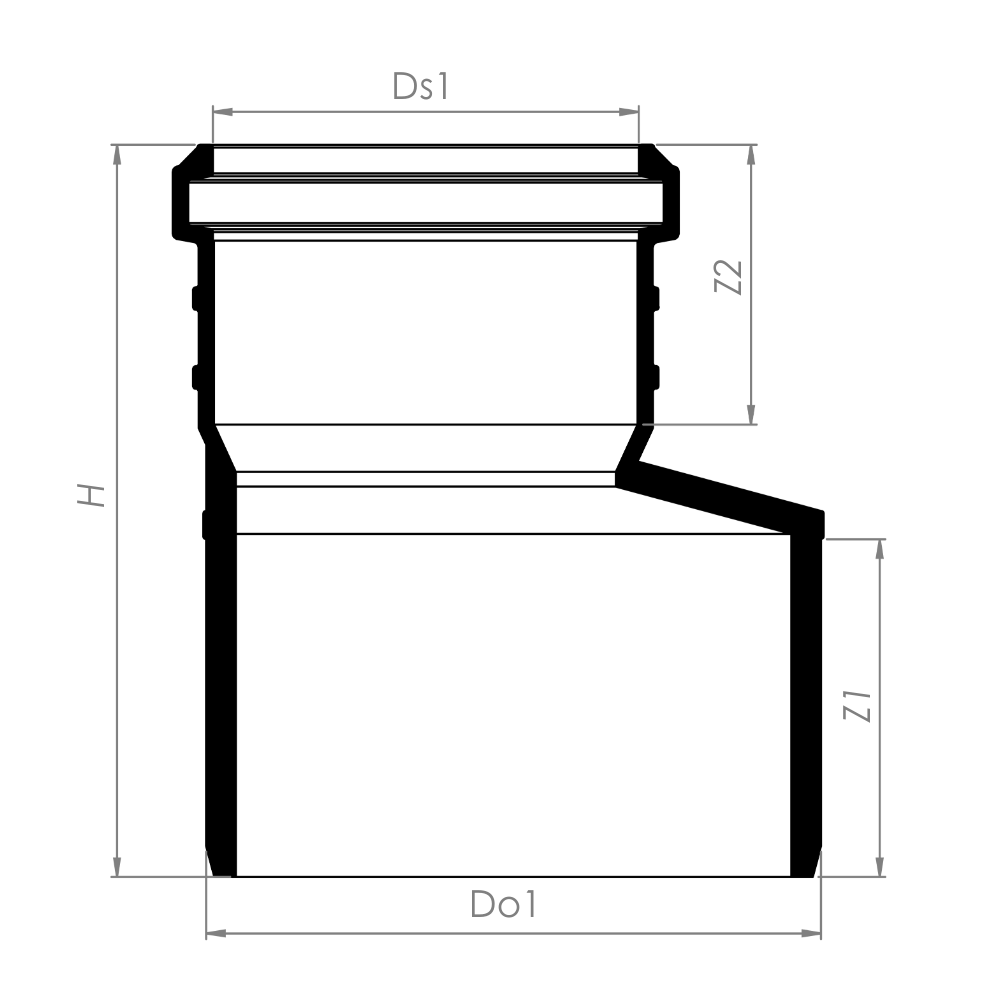

Reducer

| Diameter DN | Ds1 mm | Do1 mm | Z1 mm | Z2 mm | H mm |

|---|---|---|---|---|---|

| 40/32 | 32 | 40 | 42 | 32 | 92 |

| 50/32 | 32 | 50 | 42 | 50 | 107 |

| 50/40 | 40 | 50 | 42 | 48 | 106 |

| 75/40 | 40 | 75 | 42 | 59 | 120 |

| 75/50 | 50 | 75 | 47 | 55 | 124 |

| 90/75 | 75 | 90 | 51.5 | 62 | 137 |

| 110/50 | 50 | 110 | 46 | 62 | 150 |

| 110/75 | 75 | 110 | 50 | 62 | 142 |

| 110/90 | 90 | 110 | 55 | 72 | 156 |

| 160/110 | 110 | 160 | 64 | 53 | 201 |

End Cap

| Diameter - DN | Ds1 - mm | Z1 - mm |

|---|---|---|

| 32 | 32 | 38 |

| 40 | 40 | 46 |

| 50 | 50 | 51.3 |

| 75 | 75 | 56.5 |

| 90 | 90 | 61.5 |

| 110 | 110 | 65.3 |

| 160 | 160 | 77 |

Q Trap 45°

| Diameter - DN | Angle | Ds1 mm | Do1 mm | Z1 mm | Z2 mm | H mm |

|---|---|---|---|---|---|---|

| 110 | 45 | 110 | 110 | 56 | 170 | 228 |

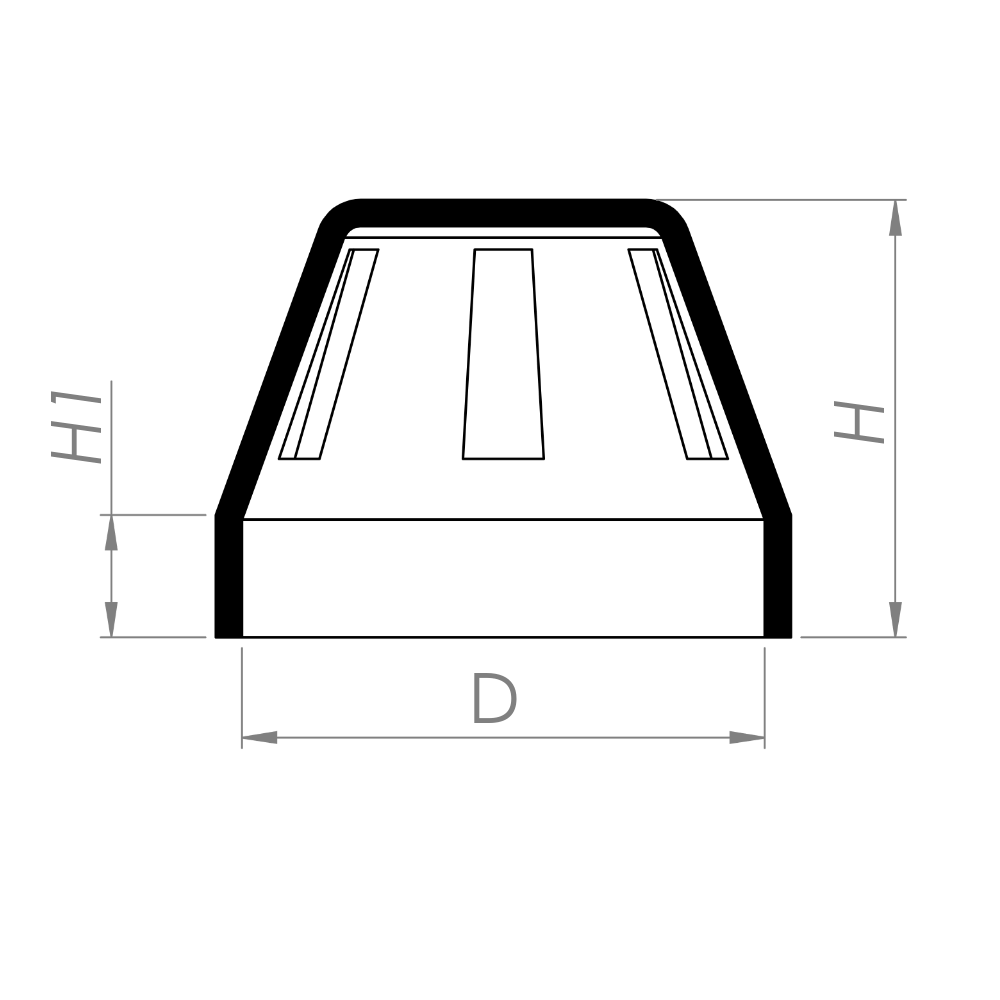

Vent Cowl

| Diameter mm | H mm | H1 mm |

|---|---|---|

| 110 | 89 | 26 |

| 160 | 115 | 32 |

Multi Floor Trap

| Diameter DN | Ds1 mm | Do1 mm | Do2 mm | Do3 mm | Do4 mm | Z1 mm | H mm |

|---|---|---|---|---|---|---|---|

| 110 | 110 | 75 | 50 | 50 | 50 | 45 | 205 |

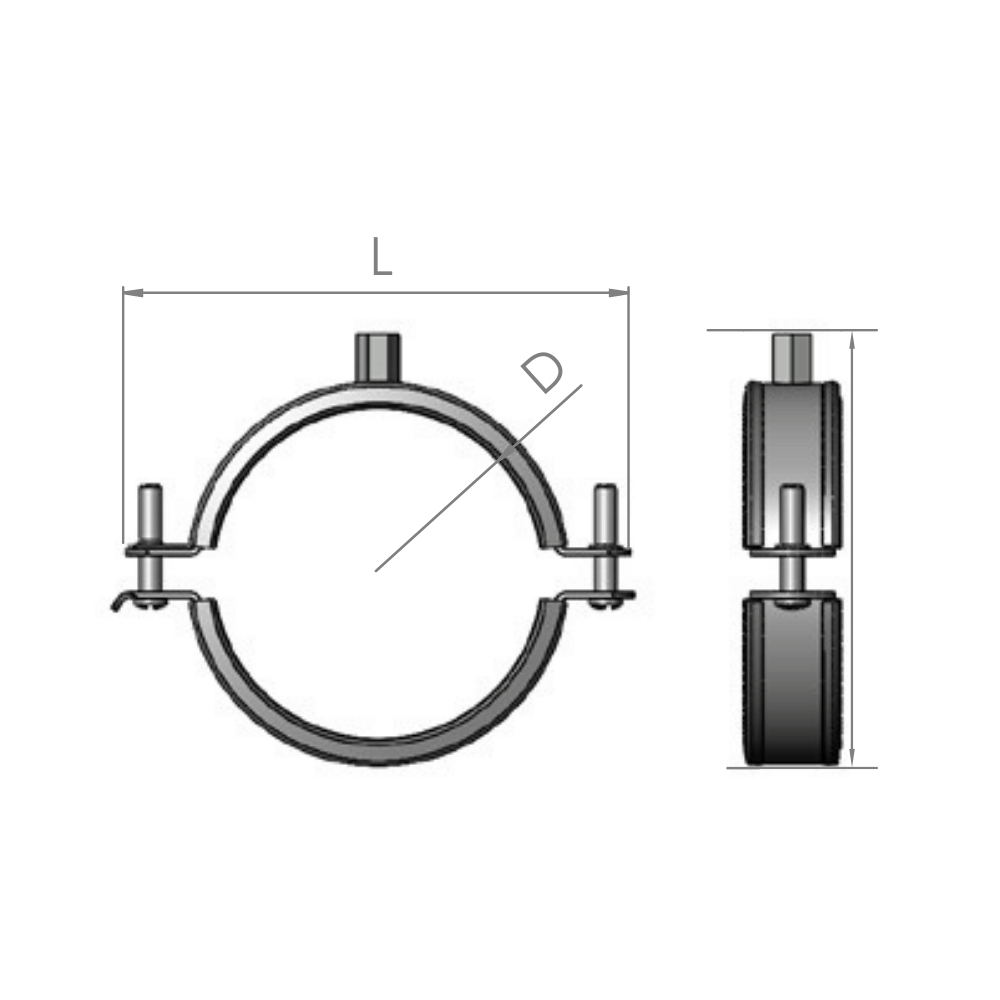

Clamps - Walraven BISMAT 1000

| D | DN | B | H1 | h1 | F |

|---|---|---|---|---|---|

| 75 | 70 | 144 | 140-150 | 93-102 | 650 |

| 90 | 80 | 164 | 147-154 | 102-109 | 820 |

| 110 | 100 | 176 | 175-185 | 110-120 | 820 |

| 160 | 150 | 233 | 235-245 | 137-147 | 820 |

Clamps - Rubber Inlet Brackets

| D | H | L |

|---|---|---|

| 32 | 58 | 75 |

| 40 | 78 | 98 |

| 50 | 102 | 125 |

| 75 | 116 | 141 |

| 90 | 145 | 159 |

| 110 | 158 | 176 |

| 160 | 239 | 248 |

Plastic Clamps

| D | h | B | h2 | H |

|---|---|---|---|---|

| 28-32 | 33 | 41 | 10 | 53 |

| 35-40 | 41 | 48 | 12 | 66 |

| 44-50 | 46 | 56 | 12 | 76 |

| 71-76 | 73 | 105 | 28 | 114 |

| 88-93 | 83 | 114 | 32 | 133 |

| 109-115 | 95 | 146 | 35 | 165 |