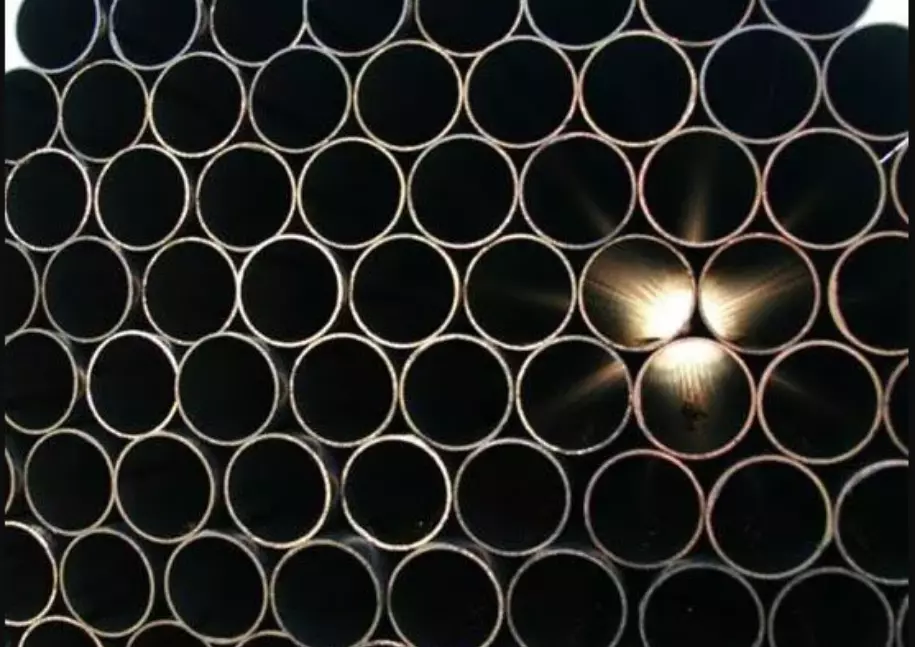

PVC Pipes

PVC pipes the most popular choice for transportation of drinking water, Electrical Ducting and Sewage lines. It has been proven that plastic pipes are the ideal products for today's extensive continuum of commercial, residential and industrial sector applications for withstanding resistance to wide range of chemicals, heat and pressure. PVC pipes are easy to install, lightweight, strong and durable, making them cost-efficient and sustainable. The smooth surface of PVC pipes also supports faster water flow due to lower amounts of friction than piping made from other materials such as concreate or metal.

Our industrial PVC pipe and fittings are manufactured in both inch and metric industry standards and conform to all relevant to different international Standards. PVC pipe can have a solid wall or cellular core construction and is produced by extrusion in a range of sizes and dimensions. In order to create a cellular core, at least three layers of material must be simultaneously extruded into the pipe wall: a solid top shell, a cellular core intermediate surface, and a solid interior surface. For pressure and non-pressure purposes, PVC pipe is produced in accordance with a number of international standards.

Polyfab UPVC pipes and Fittings outperform conventional systems in utility and applications due to their superior physical, chemical, and mechanical properties.The "U" in UPVC stands for "Un-plasticized," meaning that no plasticizer has been added to make it flexible (such as is done with tarpaulins). Therefore, it is more accurate to refer to almost any rigid PVC commodity as either UPVC or PVCU. The UPVC pipe material is hard and brittle without softening chemicals. This prevents it from being used for pipes and other flexible applications, although it still has a useful application in building. It is utilized as siding or weatherboarding material on the external walls of dwellings in many different nations because it is resistant to prolonged exposure to heat and sunlight.

The basic polymer is PVC resin suspension grade which is mixed with additives such as color, filler, lubricants, stabilizers etc. in accordance with a recipe determined by the properties of the finished product. The mixed PVC compound is transported for the extrusion process for the manufacturing of PVC pipes and the same way it is transported to the injection molding process for the manufacturing of PVC fittings.

Download CatalogueAdvantages of uPVC Pipes

- Non-corrosive: uPVC Pipes are not attacked by acids, alkalis, oil and salts etc, because UPVC material is chemically inert.

- Insulator: UPVC is an excellent electrical and is used as an insulation on electrical wires & cables and used as ducts for electrical and communication cables

- Mechanical Strength: UPVC pipes will not dent or flatten under pressure because of high tensile & impact strength.

- Low Thermal Conductivity: UPVC has low co-efficient of thermal conductivity therefore there is no heat loss or gained.

- Fire proof: UPVC pipes will not support combustion and in the event of fire, flames are unable to spread along the pipes

- Flow efficiency: UPVC Pipes have smooth & glossy surfaces which discourage the formation of scale and deposits.

- Light Weight: UPVC Pipes are of less weight compared to cast iron, asbestos & cement pipes, due to this reason there is a reduction in manpower & installation cost.

- Sanitary: UPVC pipes are completely non-toxic & do not affect the taste, smell or color of liquid, nor react with any liquid to cause a precipitant.

- Cost: UPVC is one of the least expensive materials used in manufacturing of pipes and fittings.

Type of uPVC Pipes

Drainage Pipes

uPVC Drainage pipes are the best option for the drainage application because of the sufficient strength and in the environmental and chemical conditions of the site, such as those in soil, water & corrosion. Drainage pipe & fittings provide a suitable solution for soil, waste, Gravity & Sewer applications.

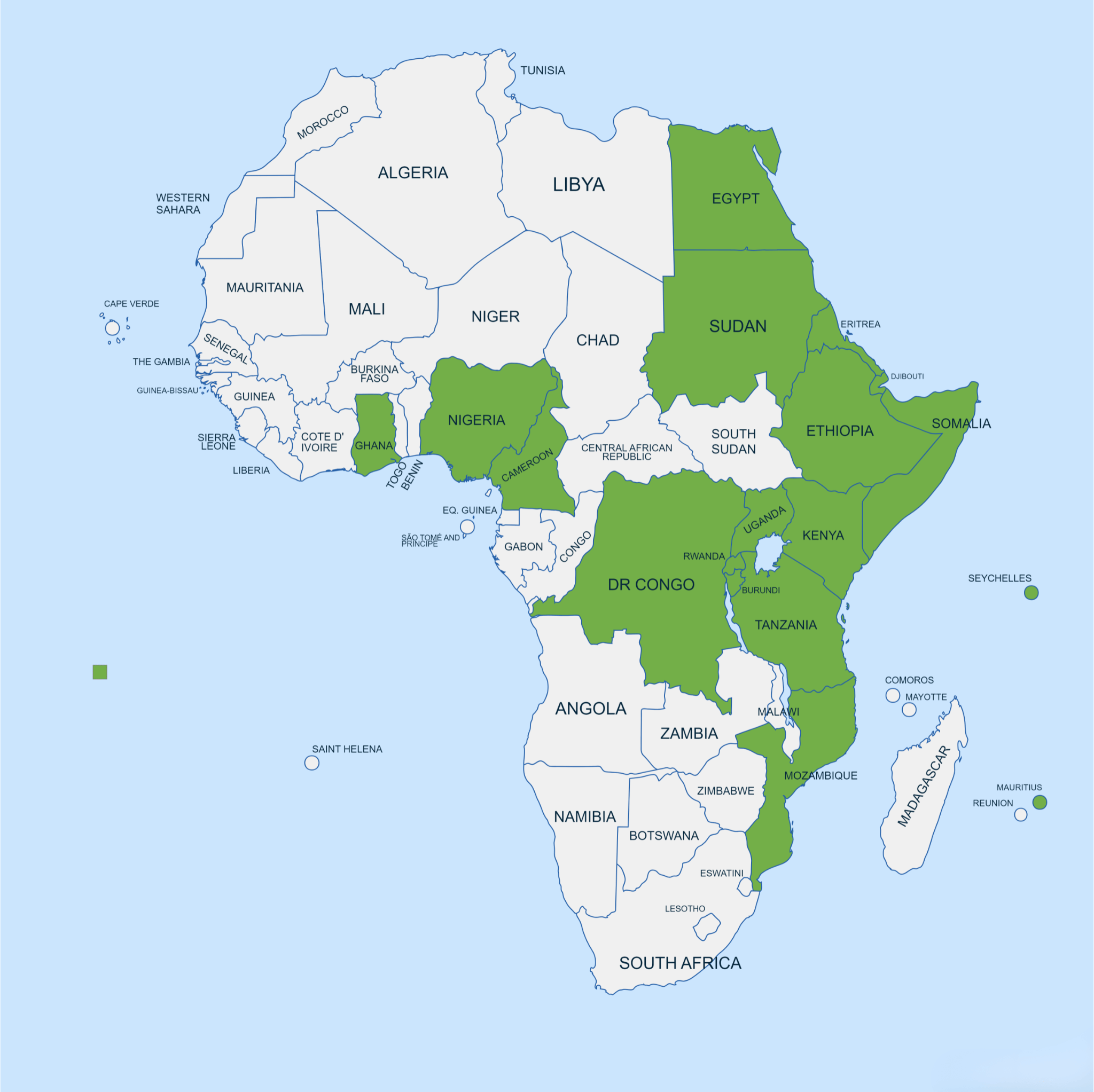

When do you need drainage pipes in bulk to sell? You must conduct your own research to determine which company exports drainage pipes at budgeted prices. Following that, you should have no trouble locating the best Drainage Pipes Exporters in Ethiopia, Kenya and Ghana. It is advantageous to save a lot of money and to purchase in bulk what you require.

Do you wish to purchase a drainage pipe in Ethiopia, Kenya, or Ghana? To accomplish this, you must work with the right exporter who can assist you in obtaining the material in bulk. Polyfab sells high-quality drainage pipes at low prices in Ethiopia, Kenya, and Ghana. Polyfab provides the best drainage pipes in Accra, Addis Ababa, and Nairobi.

Download Catalogue

Underground Drainage

Underground Drainage is one of the most important infrastructure projects for an urban area, as it directly affects its citizens’ health and quality of life. Collection of waste water is implemented using pipes that are installed underground. Their construction specifications are very strict and demanding, covering lifetime, resistance to mechanical and chemical corrosion, leak-proof, ease of use, hydraulic performance, etc.

- Specially designed for underground non-pressure applications

- Easy to install

- Hygienic and leak proof

- Smooth inner bore for better flow rate of water

- Lower installation & maintenance cost as compared to conventional pipes

- Excellent stiffness and impact resistance

- Easy of jointing when using uPVC joints & fittings

Download Catalogue

Aboveground Drainage

Polyfab above ground drainage systems provide complete control of soil & waste water discharge and collection to drainage, all while maintaining the ease, flexibility, and strength of a lightweight plastic product that is ideal for applications ranging from new construction to repair and maintenance.

Downpipes are typical components of above-ground drainage systems for managing precipitation, and soil and waste systems transport wastewater from individual houses to below-ground sewage systems. There is a performance warranty on the UV-stabilized plastic guttering and downpipes from Polyfab, and they are available in a variety of shapes and diameters to fit practically any project or property.

Download Catalogue

BSI Kitemark™

BSI Kitemark is a quality mark that shows a product or service meets the applicable and appropriate British European, international & other recognized standard for quality, safety, performance and trust. A Standard is a published specification that establishes a common language, and contains a technical specification or other precise criteria and is designed to be used consistently, as a rule, a guideline, or a definition. Standards are applied to many materials, products, methods and service. They help to make life simpler, and increase the reliability and the effectiveness of many goods and services we use.

POLYFAB brand uPVC pipes & fittings for underground and above ground drainage applications are approved by the British Standard Institute and are awarded the Kitemark Quality Certificate where applicable. POLYFAB drainage system, are manufactured according to the latest European Standards BSEN1401 and BSEN 1329 and are subject to very strict Quality Policy supervised by BSI which enabled POLYAB systems to be approved by the most prestigious International Institutes.

Pressure Pipes for Potable & Irrigation Applications

Polyfab manufactures a wide variety of high-quality PVC pressure pipes and fittings for complete pipe system requirements. Polyfab offers a superior range of PVC pressure pipe systems for a wide range of project requirements, using only the highest quality raw materials and manufactured to meet Polyfab's International quality control standards. PVC pressure pipes are made from Poly Vinyl Chloride resin that has been mixed with stabilisers, lubricants, and pigments. They are known as unplasticised PVC or PVC-U.

Download Catalogue

Duct Pipes

PVC duct pipe is suitable for non -pressure cabling & conduit applications. PVC duct pipe is resistant to corrosion and degradation caused by chemicals that commonly attack metallic pipe. Polyfab ductwork pipe is extruded with different International Standard specification such as BSEN, ASTM, BS, ISO, NEMA TC, Etisalat/DU spec. and other Service duct pipes.

Our PVC duct pipe is commonly used for wide verity of infrastructure application, telephone cables, High voltage underground cables, Street lighting cables, Power plant, Factory & other Industrial applications. Over the life of a well-designed ventilation system, Polyfab PVC duct pipe can provide significant cost savings. This pipe type and brand are designed and engineered to have a high tensile strength and modulus of elasticity over a wide temperature range. Polyfab duct has improved corrosion resistance, chemical resistance, low weight, low heat conductance, good electrical properties, and is simple to handle and install. PVC ducting pipe is chemically resistant to a wide range of bases (caustics), acids, ionic / salts, oxidants, halogen compounds, and aliphatic solutions.

Download Catalogue

PVC Pipes Ethiopia

Polyfab is a major supplier of PVC pipes, offering manufacturers, wholesalers, and distributors throughout Ethiopia plastic pipes, tubes, and goods made to order. Polyfab offers a large variety of robust PVC pipes for use in irrigation, electrical and telecommunication lines, pressure and non-pressure water supply, and wastewater. A large variety of high-quality uPVC pipes and fittings that meet international quality requirements are offered by Polyfab, which developed its facilities for uPVC pipes in order to maintain its leading position in the Ethiopian marketplace.

PVC Pipes Ghana

Polyfab For many years has served Ghana's water and electrical engineering markets as the primary supplier of high-quality, unplasticized polyvinyl chloride (uPVC) and PVC pipes and fittings. Using cutting-edge machinery and the most recent technologies, we manufacture pipes that precisely adhere to global standards. All of the Polyfab pipes are put through a thorough testing process in our laboratory before being approved by the Ghana Standards Board and strict British and Metric Standards. Polyfab places a lot of focus on workforce development as a way to quickly address our client’s issues. In order to provide our clients with technical advice on the proper usage of Polyfab uPVC and HDPE pipes and fittings, our team of knowledgeable engineers and technical consultants is available at all times.

PVC Pipes Kenya

The enhanced physical, chemical, and mechanical qualities of Polyfab uPVC pipes and fittings allow them to perform better than conventional systems in utility and applications. Polyfab cutting-edge facility and highly skilled team have long made sure that high-quality uPVC pipes are always available to meet the demand of our customers. Polyfab manufactures pipes using cutting-edge extrusion technology for a variety of uses in the irrigation, Drainage, Potable water supply, electrical power distribution, and telecommunications industries in Kenya. The industrial and economic development of Kenya region is greatly aided by the high-caliber goods of Polyfab. Our substantial clientele base, both within and outside of Kenya, attests to this.